Repacking

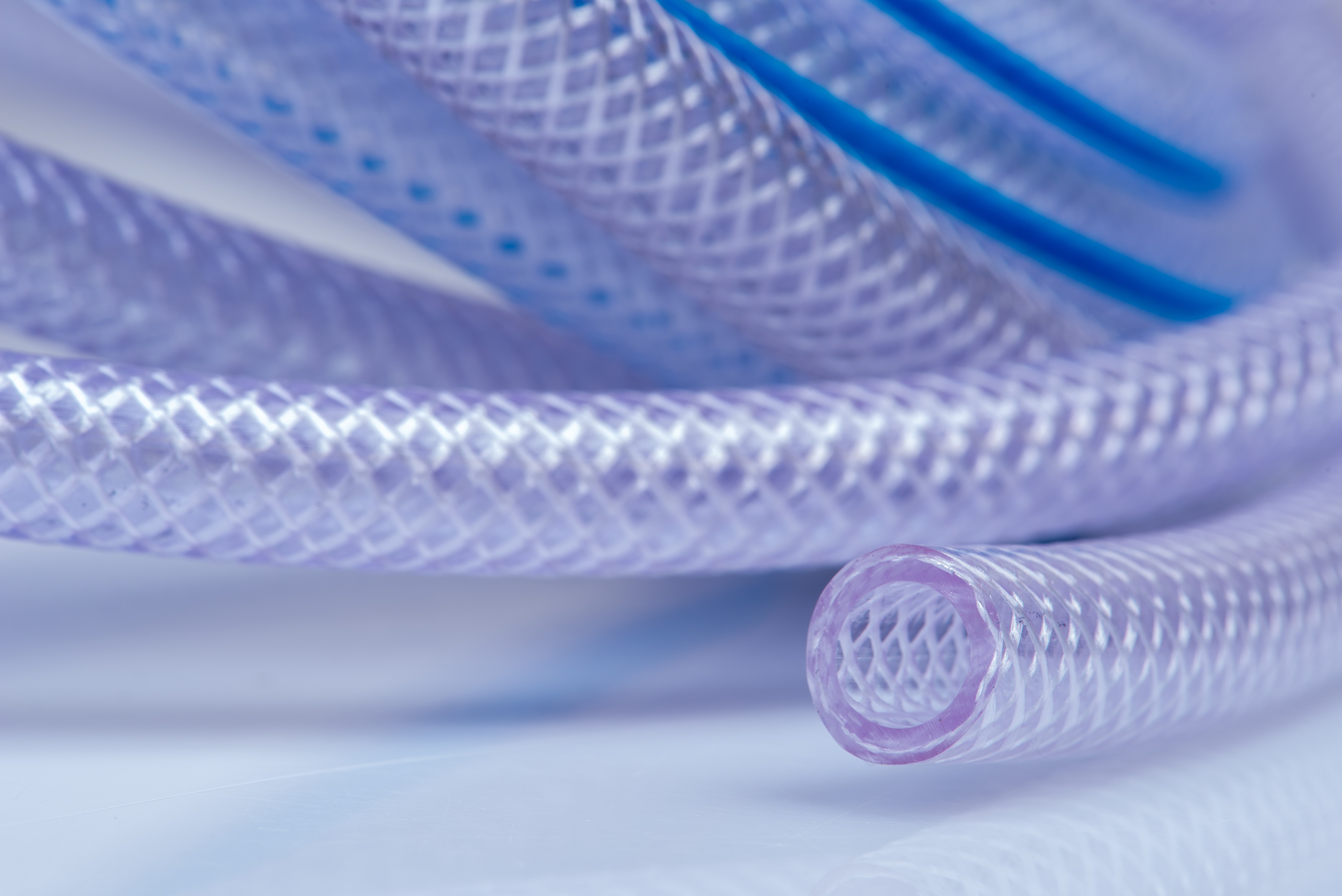

Sort bulk quantities into smaller units, poly bag, heat seal and apply product label

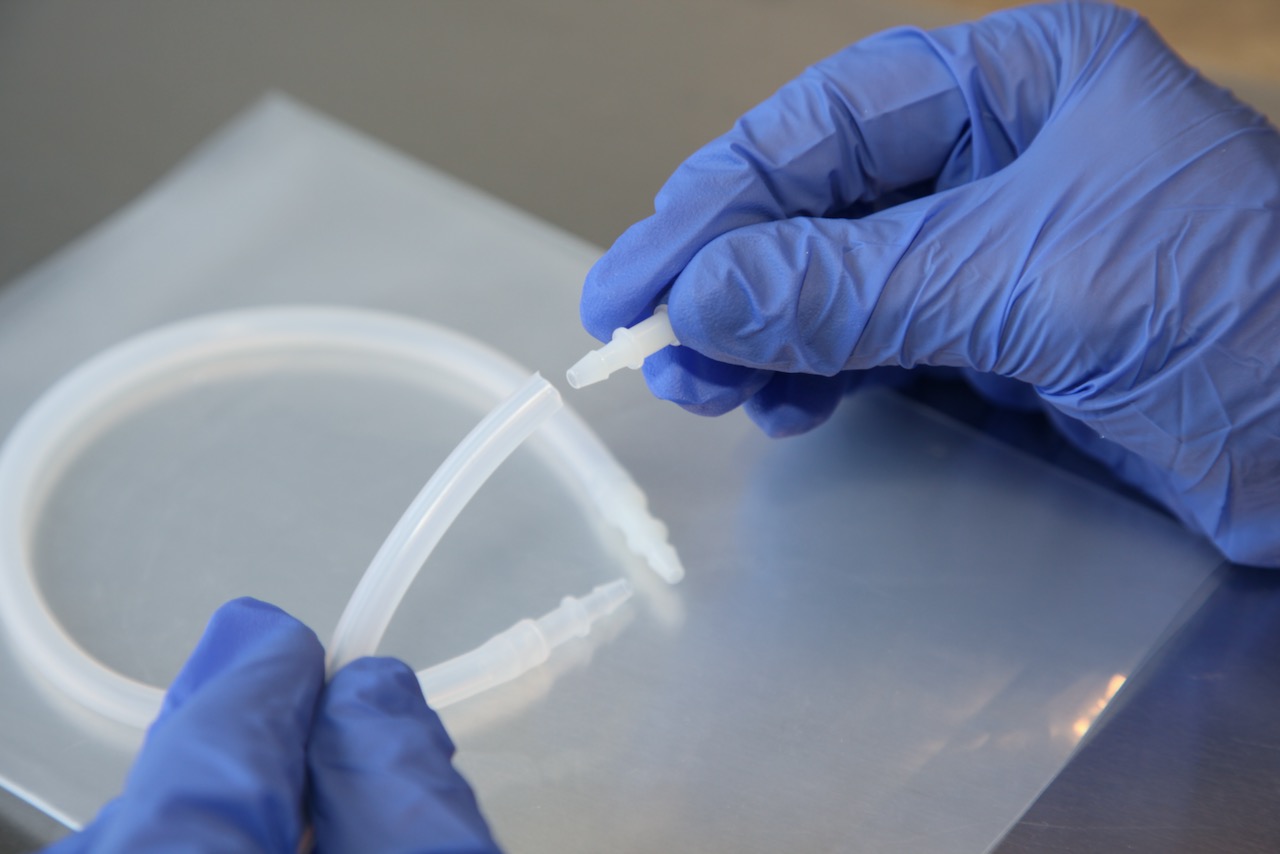

Custom packing of pharmaceutical, life science and electronic materials in a clean, controlled environment that meets and exceeds ISO Class 7 requirements

Materials are sterilized within a Laminar flow cabinet and then repacked, kitted, assembled, poly bagged and heat sealed within the unit

Laminar flow cabinet ULPA filters are are 99.999% effective at particle sizes between 0.1 to 0.3 um

Germicidal ultraviolet lamps are used to provide a sterile work zone for aseptic techniques

HEPA filter air purifiers continually filter the work environment

Particulate counter continuously monitors the quality of the environment

Employees wear protective garments, masks, gloves, hair caps and shoe covers to avert contamination

Sort bulk quantities into smaller units, poly bag, heat seal and apply product label

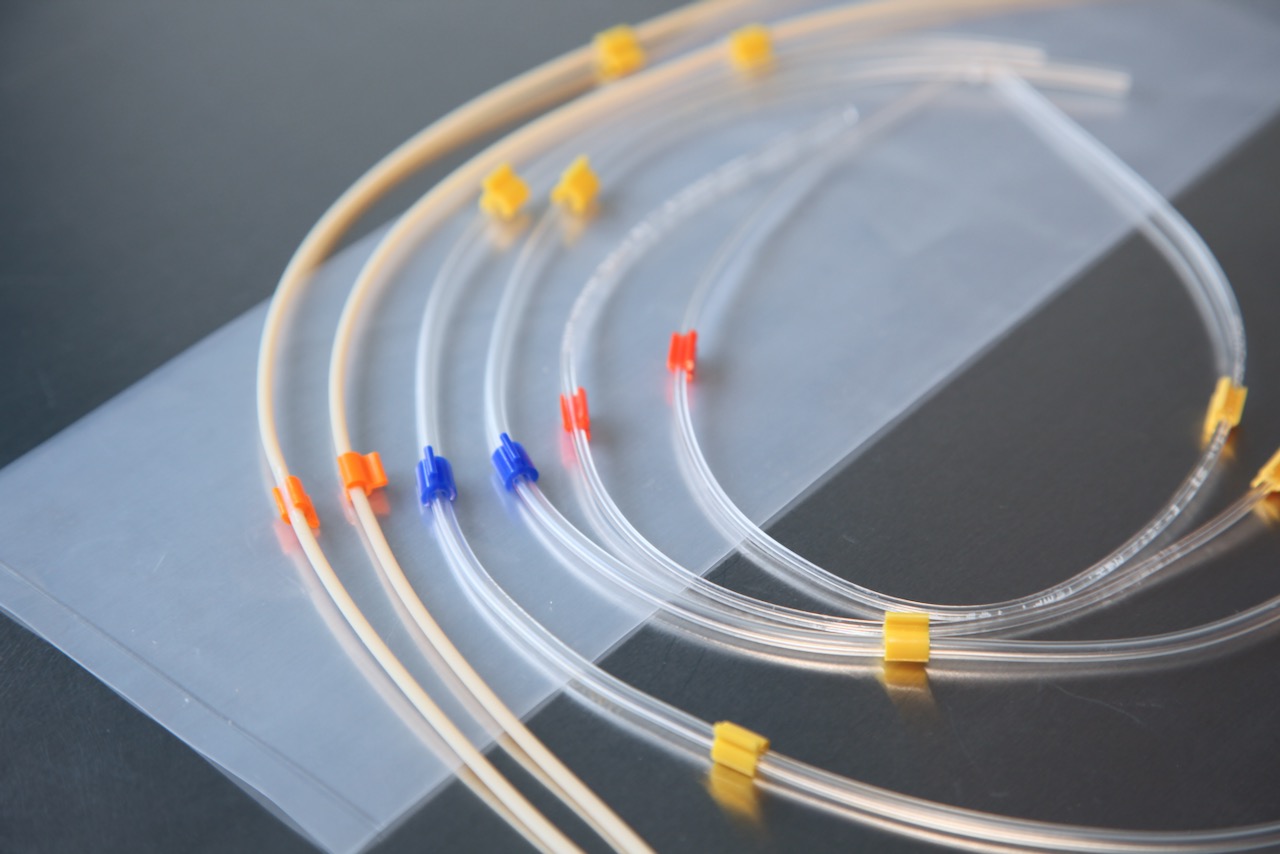

Package multiple components, poly bag, heat seal, apply product label, and sort by kit version

Hand assemble components, poly bag, heat seal, apply product label, package securely for transit

Create custom labels for products and kits